In today’s fast-paced manufacturing landscape, precision and efficiency are paramount. As businesses strive to meet ever-increasing demands for quality and speed, integrating CNC milling into the production process has emerged as a game changer.

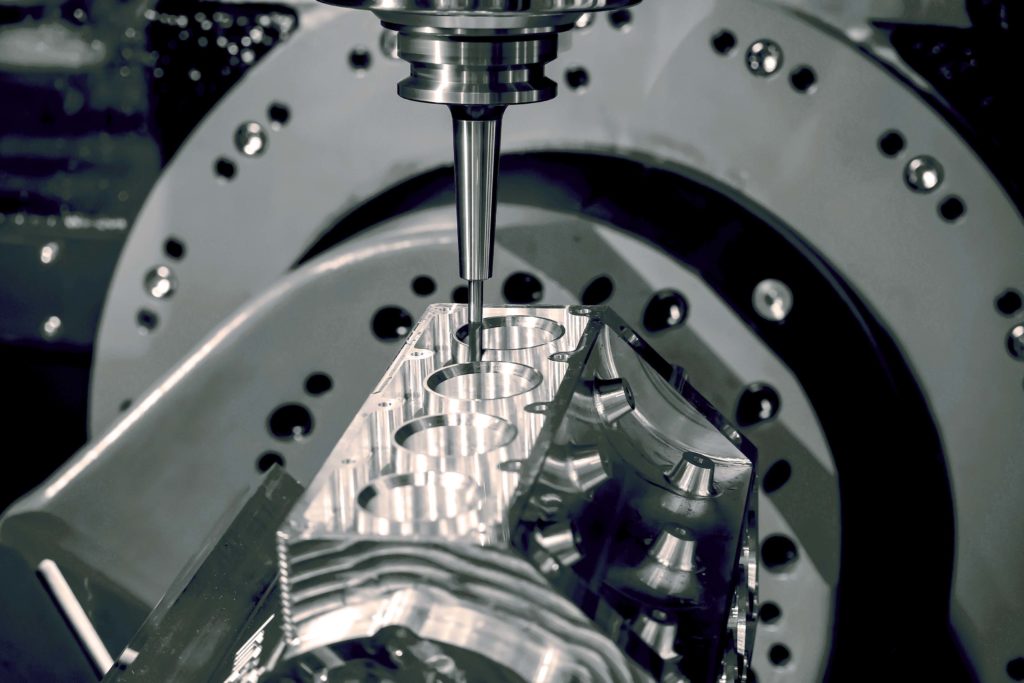

This advanced machining technique not only enhances accuracy but also streamlines workflows, allowing for the creation of intricate parts with unparalleled consistency. However, implementing CNC milling requires a well-thought-out approach.

In this article, we will guide you through a comprehensive three-step process to seamlessly incorporate CNC milling into your manufacturing operations. Whether you’re a seasoned professional or a newcomer to the field, understanding these steps will empower you to harness the full potential of CNC technology, driving both innovation and cost-effectiveness in your production line.

Join us as we delve into the intricacies of this transformative technique, unlocking new possibilities for your business.

Assess Your Manufacturing Needs

Before diving into the implementation of CNC milling machining parts, it is essential to conduct a thorough assessment of your manufacturing needs. Start by evaluating the complexity of the parts you wish to produce—are they intricate components with tight tolerances or simpler shapes? This understanding will steer you toward the right type of machinery and tooling required for your production line.

Next, consider your production volume; will you be running large batch orders or focusing on custom, small-scale projects? These choices drastically affect machine selection and workflow design. Additionally, don’t overlook the materials you’ll be working with—different CNC mills accommodate varying materials, influencing not just performance but also cost-effectiveness.

Finally, integrating your existing systems and evaluating your workforce’s skill set are crucial for seamless adoption. By addressing all these factors, you’ll be well-equipped to choose a CNC milling process that perfectly aligns with your manufacturing objectives.

Selecting the Right CNC Milling Equipment

Selecting the right CNC milling equipment is a pivotal step that can dramatically influence the efficiency and quality of your manufacturing process. First, consider the specific materials you’ll be working with; whether it’s aluminum, steel, or specialized composites, each requires different capabilities.

High-speed machining might be essential for softer materials to enhance productivity, while precision milling is crucial for hard alloys. Next, evaluate the machine’s specifications—look for characteristics like spindle speed, feed rate, and the number of axes.

These factors not only affect the cutting efficiency but also the complexity of parts you can produce. Finally, weigh the importance of the software integration and the machine’s compatibility with your existing systems; an intuitive interface can significantly streamline operations.

Remember, investing in the right equipment now can save you from unnecessary headaches and costs down the line, enabling a smoother path toward manufacturing excellence.

Integrating CNC Milling into Your Workflow

Integrating CNC milling into your workflow can be a transformative step, but it requires a thoughtful approach. First, assess your current manufacturing processes; identify areas where CNC milling can enhance precision or efficiency.

Perhaps it’s a component that demands intricate details or a part that requires rapid production without sacrificing quality. Next, take a gradual approach to implementation—consider starting with a single milling machine, allowing your team to adapt and learn as they go.

This not only minimizes disruption but also opens the door for iterative improvements. Don’t forget to invest in training and skill development, ensuring your workforce is well-equipped to harness the full potential of this technology.

Ultimately, by weaving CNC milling into the fabric of your operation, you’re setting the stage for increased productivity and innovation while fostering a culture of continuous improvement.

Conclusion

In conclusion, integrating CNC milling machining parts into your manufacturing process can significantly enhance efficiency, precision, and overall production quality. By following the three-step guide outlined in this article—assessing your needs, choosing the right CNC machinery, and optimizing your workflow—you can seamlessly implement this technology and harness its benefits.

As you embark on this journey, remember that understanding the capabilities of CNC milling will not only improve your operations but also position your business for future growth in an increasingly competitive market. Embrace the transformation, and watch as your productivity thrives.

HQ Grande Prairie HQ Grandie Prairie is an online news portal aimed at providing latest day to day happenings of the World to its viewers.

HQ Grande Prairie HQ Grandie Prairie is an online news portal aimed at providing latest day to day happenings of the World to its viewers.